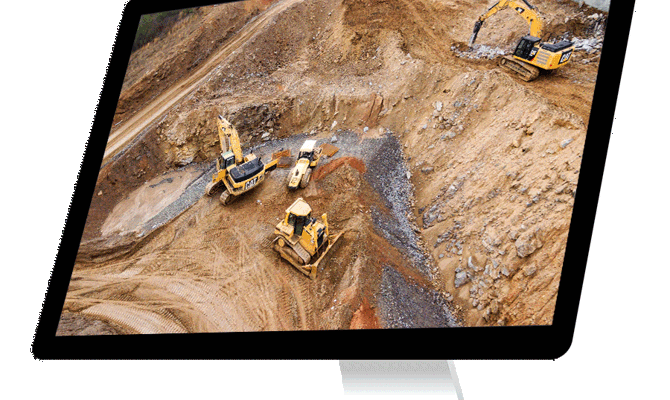

In this Q&A, MonuRent, Nigeria, shares their valuable industry insights on how technology and digitalisation are redefining job sites for the better.

How is technology changing the industry in Nigeria?

Global mining has been at the forefront of operational enhancing technology advances in recent years. New systems, developed by OEMs and mining operators alike, have driven a thirst for exciting efficiency gains in both production and maintenance departments. Nigeria is joining the data age by embracing such platforms to do everything from Greenfield Pit design to improving existing operations by finding the safest and most cost-effective way to run the projects offline, before implanting sometimes very costly changes.

Clients are no longer only looking for the cheapest miner, but the smartest ones. By being flexible, open to new improvements and using technology to our advantage, MonuRent has become extremely competitive in overall project performance, which feeds back to the best result for our clients' bottom line.

Why is asset connectivity and telematics software like VisionLink® so integral to your daily operations?

Without our operating systems across MonuRent, you could liken any given operation to running in the dark. As our operations in Nigeria advance, they become more remote and broadly distanced so it can be relatively difficult for key stakeholders to keep an eye on everything unless they have the ability to use and effectively interpret telematics.

For example, if we are in Lagos meeting with OEMs, we do not have to rely on word of mouth about what is happening, we can now log in and see what each of our machines are doing and answer our own questions definitively. We can see where are how much a machine is operating and give remote instructions to onsite teams to implement. This has resulted in improved mining techniques, operator training and usage of the machines, and cut back on idle time as well as damages.

In addition to production gains these systems offer an enhanced ability to enforce security. Unfortunately, theft is part and parcel with any mining operation in the world, so these advanced systems can allow each department to remotely monitor everything from machine idling vs working (fuel burn) using VisionLink® to facial recognition clock in/out of employees using biometrics, which greatly reduces MonuRent's losses on a daily, weekly and monthly basis.

What has been the single piece of technology introduced in recent times into your business that has really seen performance improvements?

Thus far the largest system implementation has been VisionLink® from Cat. In the future we plan on bringing in new and exciting telematics, CMMS software incorporating maintenance, logistics, procurement, and inventory management, and further rolling out our trial biometrics system.