Fill out our form with your model of interest and we'll send you a downloadable brochure or technical specifications document.

Cat® draglines offer the lowest material removal cost per ton, consume less power and emit fewer greenhouse gases than other methods of overburden removal, making them the most productive and environmentally friendly excavators in the industry. The Cat® 8200 offers all the innovative technology of our flagship model — the 8750 —but on a mid-range size scale. Along with a lower capital outlay compared to larger draglines, the 8200’s unique combination of technology, size and long operating life ensures the low total cost of ownership you need for a strong return on your investment. And like all Cat draglines, the 8200 is supported by a team with a century of experience, institutional knowledge and unmatched expertise.

Rear ingress/egress door with no-step floor to prevent trip hazards, particularly in cases of emergency where rapid exit from the…

Application engineers who work collaboratively with mines, considering factors such as digging environment, mine life, mine plan a…

State-of-the-art operator cab that is the product of a multi-year collaboration between Caterpillar, mining companies and operator…

Improved service access with walkways across the machine, plus easy accessibility to the base via manholes inside and outside of r…

Boom and Tri-Structures manufactured using cold-weather, impact-resistant, high-strength steel with select welds of full penetrati…

Equipped with AC IGBT Electrics, which deliver superior availability — routinely greater than 95% — thanks to fewer components, in…

Equipped to use Cat MineStar™ Health, which delivers critical event-based machine condition and operating data, comprehensive equi…

Full mechanical component upgrades for existing draglines, with Finite Element Analysis expertise to ensure that replacement parts…

Multiple tip options, including Heavy Duty Below Centerline, which is designed for extreme top abrasion and high-impact environmen…

Unmatched institutional knowledge of current and legacy dragline models to ensure informed upgrade recommendations, leading to mor…

Offers the lowest material removal cost per ton, consumes less power and emits fewer greenhouse gases than other methods of overbu…

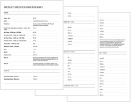

| Specification | Value |

| Bucket Capability | 46-61 m3 (60-80 yd3) |

| Boom Length | 100 m (328 ft) |

| Working Weight - Approximate | 3.8-4.1 million kg (8.5-9.1 million lb) |

| Specification | Value |

| Rated Suspended Load | 136 077-181 437 kg (300,000-400,000 lb) |

| Bucket Capabilities | 46-61 m3 (60-80 yd3) |

Learn more information about the Cat 8200 Dragline.

Download (2.22 MB, PDF)From pre-purchase consults to end-of-lifecycle benefits, Mantrac informs, advises and partners with you.

Speak with the Sales Team to learn the latest prices and information on products that can deliver value and help transform your business.

Find the perfect machine or equipment solution by contacting one of our local specialists. They are on standby, ready to help you solve your operational challenges.

Mantrac Ghana Ltd.

Ring Road West

North Industrial Area

P. O. Box 5207

Digital Address

GA134 GA-134-8364

5 Flo Oyeo RD

Accra

Ask an Expert Today!