Fill out our form with your model of interest and we'll send you a downloadable brochure or technical specifications document.

Built on the platform of our most popular underground loaders, the new R2900 XE is the first Cat® diesel electric underground LHD. It’s a productive, powerful, reliable machine built to meet the underground mining industry’s need for bigger payloads, faster loading and reduced emissions.Its powerful diesel electric drive engine is EU Stage V compliant, and it offers the power to match its class-leading 18.5-tonne . The R2900 XE is highly productive, with smooth and quick machine responses combined with improved digging and tramming performance. Employing electric drive components reduces fuel burn and improves productivity — helping mines reduce greenhouse gas emissions and carbon footprint.

Improvements in visibility, with lighting and camera coverage, including optional side and rear view cameras with color display, a…

Rollover Protective Structure (ROPS) and Falling Objects Protective Structure (FOPS) are resiliently mounted to the frame to isola…

The R2900 XE delivers a 20% increase* in productivity thanks to a number of new and improved features.An 18.5 tonne (20.4 tonne) p…

The R2900 XE employs a high efficiency electric drive system and is powered by a quiet, reliable and durable Cat® C15 engine.With…

The R2900 XE’s bucket has been redesigned for increased strength and simplified serviceability. Wear bars can be replaced more eas…

By eliminating castings and reducing weight, we’ve increased the life and strength of the frame without sacrificing performance.Th…

Electric drive system with fewer moving parts and parts than traditional torque converter and mechanical transmission systems exte…

Factory-ready for remote operation and can be equipped with the industry-proven Cat® MineStar™ Command for underground, which offe…

Ongoing research and development into engine compatibility with diesel fuel blended with lower-carbon intensity fuels such as biof…

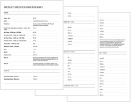

| Specification | Value |

| Engine Model | Cat® C15 |

| Engine Power - Stage V Engine - ISO 14396:2002 | 335 kW |

| Engine Power - Tier 2/Stage II Engine - ISO 14396:2002 | 333 kW |

| Bore | 137 mm |

| Stroke | 172 mm |

| Displacement | 15.2 l |

| Note (1) | Power ratings apply at a rated speed of 1,600 rpm for Tier 2/Stage II model engine when tested under the reference conditions for the specified standard. |

| Note (2) | Power ratings apply at a rated speed of 1,600 rpm for Stage V model engine when tested under the reference conditions for the specified standard. |

| Note (3) | All rating conditions are based on ISO/TR 14396, inlet air standard conditions with a total barometric pressure of 100 kPa (29.5 in Hg), with a vapor pressure of 1 kPa (.295 in Hg), and 25° C (77° F). Performance measured using fuel to EPA specifications in 40 CFR Part 1065 and EU specifications in Directive 97/68/EC with a density of 0.845-0.850 kg/L @ 15° C (59° F) and fuel inlet temperature 40° C (104° F). |

| Note (4) | Minimal engine derating* required up to 2926 m (9,600 ft) at rated speed for Stage V engines and 3505 m (11,500 ft) for Tier 2/Stage II equivalent engines. |

| Note (5) | Optional DPF (Diesel Particulate Filter) Package available. |

| Note (6) | * <5% |

| Specification | Value |

| Nominal Payload Capacity | 18.500 kg |

| Gross Machine Mass | 78.089 kg |

| Shipping Weight | 59.869 kg |

| Static Tipping Load - Straight Ahead - Lift Arms Horizontal | 43.276 kg |

| Static Tipping Load - Full Turn - Lift Arms Horizontal | 37.598 kg |

| Breakout Force - Lift (ISO) | 32.500 kg |

| Breakout Force - Tilt (ISO) | 42.000 kg |

| Specification | Value |

| Operating Mass* | 55.462 kg |

| Operating Mass* - Front Axle | 24.685 kg |

| Operating Mass* - Rear Axle | 30.777 kg |

| Operating Mass + Rated Payload* | 73.962 kg |

| Operating Mass + Rated Payload* - Front Axle | 54.480 kg |

| Operating Mass + Rated Payload* - Rear Axle | 19.482 kg |

| Note | * Calculated Weight. |

| Specification | Value |

| Transmission Type | Cat switched reluctance electric drive |

| Forward - 1st (virtual) | 5.8 km/h |

| Forward - 2nd (virtual) | 9.5 km/h |

| Forward - 3rd (virtual) | 17 km/h |

| Forward - 4th (virtual) | 24.6 km/h |

| Forward - 5th (virtual) | 33.4 km/h |

| Reverse - 1st (virtual) | 6 km/h |

| Reverse - 2nd (virtual) | 10.1 km/h |

| Reverse - 3rd (virtual) | 18 km/h |

| Reverse - 4th (virtual) | 26 km/h |

| Reverse - 5th (virtual) | 32.9 km/h |

| Specification | Value |

| Lift/Tilt System - Circuit | Electro Hydraulic Controls |

| Lift/Tilt System - Pump | Variable Displacement Piston |

| Maximum Flow | 479 L/min |

| Relief Valve Setting - Main | 31.700 kPa |

| Lift Cylinder - Bore | 190 mm |

| Lift Cylinder - Stroke | 1.011 mm |

| Tilt Cylinder - Bore | 270 mm |

| Tilt Cylinder - Stroke | 458 mm |

| Specification | Value |

| Raise | 9 s |

| Dump | 2.8 s |

| Lower, Empty, Float Down | 3.5 s |

| Total Cycle Time | 15.3 s |

| Specification | Value |

| Bucket Capacities | 7.4-9.8 m³ (9.7-12.8 yd³) |

| Dump Bucket - 1 - Standard Bucket | 7.4 m³ |

| Dump Bucket - 2 | 8.6 m³ |

| Dump Bucket - 3 | 9.2 m³ |

| Dump Bucket - 4 | 9.8 m³ |

| Specification | Value |

| Outside Clearance Radius** | 7.270 mm |

| Inner Clearance Radius** | 3.391 mm |

| Axle Oscillation | 8° |

| Articulation Angle | 42.5° |

| Note | ** Clearance dimensions are for reference only. |

| Specification | Value |

| Tire Size | 29.5 R29 |

| Specification | Value |

| Engine Crankcase | 52 l |

| Propulsion Motor/Drop Box Oil | 68 l |

| Hydraulic Tank | 338 l |

| Cooling System (Engine Radiator) | 95 l |

| Cooling System (Drive Motor - secondary) | 32 l |

| Front Differential and Final Drives - With Axle Oil Cooling System | 140 l |

| Rear Differential and Final Drives - With Axle Oil Cooling System | 154 l |

| Fuel Tank | 660 l |

| DEF Tank | 34 l |

| Specification | Value |

| Standards | ISO 3471:2008 ROPS; ISO 3449:2005 FOPS |

Learn more information about the Cat R2900 XE Underground Diesel-Electric LHD Loader.

Download (2.22 MB, PDF)From pre-purchase consults to end-of-lifecycle benefits, Mantrac informs, advises and partners with you.

Speak with the Sales Team to learn the latest prices and information on products that can deliver value and help transform your business.

Find the perfect machine or equipment solution by contacting one of our local specialists. They are on standby, ready to help you solve your operational challenges.

Shanghai Offshore Office

Minhang District, Shanghai, China