Road Construction

Cat® GX Hydraulic Excavators

Cat® 426F2 Backhoe Loader

Equipment Protection Plans (EPP)

Machine Attachments

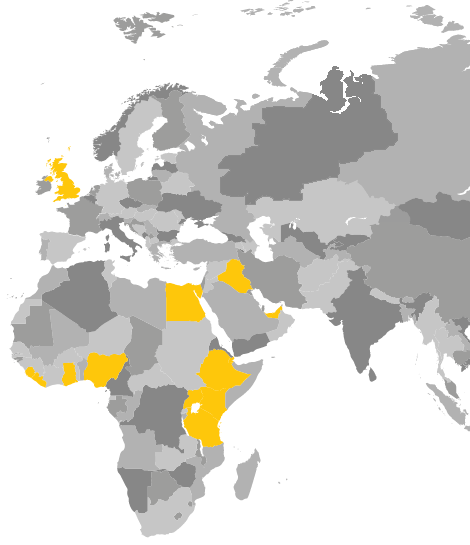

Representatives around the globe are available to help you answer your questions. Speak with the Mantrac Sales Team.

Largest AME distributor of Energy Power Investor product range

2nd largest dealer in Africa of Caterpillar mining equipment

Top 3 in AME for Advanced equipment management solutions

Largest Oil and Gas dealer in EAME and Eurasia

Winner of 2 Gold, 6 Silver and 3 Bronze Caterpillar’s Worldwide Service Excellence programme

African footprint with 61 branches, 5 component rebuild centers, 3 S.O.S. labs, 866 services techs and 346 service vehicles