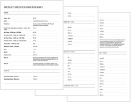

Fill out our form with your model of interest and we'll send you a downloadable brochure or technical specifications document.

The Cat® D10 Dozer is innovative by design — developed by a team of experts who follow a design approach that incorporates feedback from the field with industry-leading technologies to deliver a dozer that continues to advance with every model. The new D10 is no exception. It’s more efficient, so it burns less fuel. It’s more serviceable, so you’ll experience less downtime. It’s more durable, so you’ll spend less over its lifetime. And it’s more productive — so you’ll spend less time putting more profitability to your bottom line.

The torque converter with stator clutch automatically frees up the stator when torque multiplication is not required under low loa…

The cab is unparalleled, with enhanced ergonomics, a fully adjustable air suspension seat and and controls that are easy to access…

The operator station offers an exceptional viewing area, with a tapered hood, notched fuel tank, and narrow ripper carriage to giv…

The in-cab touchscreen Information Display is larger, faster, and more powerful with increased memory and intuitive menu structure…

Standard Dual-Tilt Automated Blade Assist (ABA) increases efficiency while reducing operator workload, making use of preset blade…

The D10 comes out of the factory ready to integrate Cat MineStar™ technology, which takes accuracy, efficiency and safety even fur…

Fully integrated Cat AutoLube Solution Replaceable push-arm trunnion bearing inserts Large engine oil sump with 50% mo…

The perfect match for the D10, Cat blades are aggressive in tough materials and offer superior loadability. Work-tool option…

Increased oil pan capacity improves oil quality and engine life. The single plane cooling system reduces heat load for longe…

The D10 is designed to use less fuel, which reduces engine emissions The Tier 4 Final engine reduces NOx and particulate mat…

| Specification | Value |

| Engine Model | Cat® C27 |

| Engine Power - Net SAE J1349/ISO 9249** - Forward | 449 kW |

| Engine Power - Gross SAE J1995* - Forward | 471 kW |

| Engine Power - Gross SAE J1995* - Reverse | 597 kW |

| Engine Power - ISO 14396* - Forward | 462 kW |

| Engine Power - ISO 14396* - Reverse | 588 kW |

| Engine Power - Net SAE J1349/ISO 9249** - Reverse | 564 kW |

| Displacement | 27 l |

| Stroke | 152 mm |

| Bore | 137 mm |

| Emissions | U.S. EPA Tier 4 Final/EU Stage V |

| Note (1) | *Excludes all fan losses. |

| Note (2) | All Engine ratings apply at 1,800 rpm. |

| Note (3) | Tier 2 equivalent rating (in FWD gears) begins altitude de-rate at 4480 m (14,700 ft). |

| Note (4) | Tier 4/EU Stage 5 equivalent rating (in FWD gears) begins altitude de-rate at 4420 m (14,500 ft). |

| Note (5) | **Net power advertised is the power available at the flywheel when the engine is equipped with air cleaner, muffler, alternator, fan, and engine emissions controls as required at 25° C ambient temperature. |

| Specification | Value |

| Engine Model | Cat® C27 |

| Engine Power - Net SAE J1349/ISO 9249** - Forward | 450 kW |

| Engine Power - Net SAE J1349/ISO 9249** - Reverse | 538 kW |

| Engine Power - Gross SAE J1995* - Forward | 471 kW |

| Engine Power - Gross SAE J1995* - Reverse | 571 kW |

| Engine Power - ISO 14396* - Forward | 464 kW |

| Engine Power - ISO 14396* - Reverse | 564 kW |

| Displacement | 27 l |

| Bore | 137 mm |

| Stroke | 152 mm |

| Emissions | U.S. EPA Tier 2 Equivalent |

| Note (1) | *Excludes all fan losses. |

| Note (2) | All Engine ratings apply at 1,800 rpm. |

| Note (3) | Tier 2 equivalent rating (in FWD gears) begins altitude de-rate at 4480 m (14,700 ft). |

| Note (4) | Tier 4/EU Stage 5 equivalent rating (in FWD gears) begins altitude de-rate at 4420 m (14,500 ft). |

| Note (5) | **Net power advertised is the power available at the flywheel when the engine is equipped with air cleaner, muffler, alternator, fan, and engine emissions controls as required at 25° C ambient temperature. |

| Specification | Value |

| Fuel Tank - Usable Volume | 1.224 l |

| Fuel Tank - Total Volume | 1.269 l |

| Specification | Value |

| Cooling System Refill – Tier 4 Final Engine | 175 l |

| Engine Crankcase Sump | 103 l |

| Power Train - Total Volume | 308 l |

| Power Train - Refill Volume | 283 l |

| Final Drives (each) | 46 l |

| Track Roller Frames (each) | 64 l |

| Pivot Shaft Oil | 36 l |

| Hydraulic System Tank | 122 l |

| Specification | Value |

| Operating Weight | 70.256 kg |

| Shipping Weight | 50.684 kg |

| Note (1) | D10 Operating Weight includes coolant, lubricants, full fuel tank, ROPS, FOPS cab, SU ABR bulldozer, dual tilt, single-shank ripper with pin-puller, fast fuel, 610 mm (24 in) ES shoes, and operator. |

| Note (2) | D10 Shipping Weight includes coolant, lubricants, 10% fuel, FOPS cab, fast fuel, and 610 mm (24 in) ES shoes. |

| Specification | Value |

| Pump Type | Variable displacement piston |

| Pump Output - Implement | 424 l/min |

| Note (1) | Implement Pump output measured are 2,010 engine rpm and 7000 kPa (1,015 psi). |

| Fan Pump | 82 l/min |

| Note (2) | Fan Pump output measured at 2,010 engine rpm and 26 000 kPa (3,771 psi). |

| Tilt Cylinder Flow - Rod End Flow | 424 l/min |

| Tilt Cylinder Flow - Head End Flow | 240 l/min |

| Lift Cylinder Relief Valve Setting | 28.000 kPa |

| Tilt Cylinder Relief Valve Setting | 26.700 kPa |

| Ripper - Lift - Relief Valve Setting | 28.000 kPa |

| Ripper - Pitch - Relief Valve Setting | 28.000 kPa |

| Tank Capacity | 122 l |

| Cylinder Sizing - Blade Lift - Bore | 140 mm |

| Cylinder Sizing - Blade Tilt - Bore | 210 mm |

| Cylinder Sizing - Ripper Shank Lift - Bore | 209.6 mm |

| Cylinder Sizing - Ripper Shank Angle - Bore | 180 mm |

| Cylinder Sizing - Blade Lift - Stroke | 1.653 mm |

| Cylinder Sizing - Blade Tilt - Stroke | 241 mm |

| Cylinder Sizing - Ripper Shank Lift - Stroke | 535 mm |

| Cylinder Sizing - Ripper Shank Angle - Stroke | 660 mm |

| Note (3) | Electro-hydraulic pilot valves assist operations of ripper and dozer controls. |

| Specification | Value |

| Shoe Type | Extreme Service (ES) |

| Width - Shoe | 610 mm |

| Shoes/Side | 44 |

| Grouser Height | 93 mm |

| Pitch | 260 mm |

| Ground Clearance | 725 mm |

| Track Gauge | 2.550 mm |

| Length - Track on Ground | 3.880 mm |

| Ground Contact Area | 4.74 m² |

| Track Rollers/Side | 8 |

| Number of Carrier Rollers | 1 per side (optional) |

| Specification | Value |

| Steering Type | Hydraulically Applied Multiple-Disc Steering Clutch |

| Brake Type | Spring Applied Multiple- Disc Brake |

| Brake Diameter | 392 mm |

| Brake Count | 10 |

| Specification | Value |

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.8 kg of refrigerant which has a CO2 equivalent of 2.600 metric tonnes. |

| Specification | Value |

| ROPS | Rollover Protective Structure (ROPS) meets the following criteria: ISO 3471:2008. |

| FOPS | Falling Object Protective Structure (FOPS) meets the following criteria: ISO 3449:2005 LEVEL II. |

| Sound | Operator Sound Pressure Level (ISO 6396:2008): 78 db(A) |

| Note | The measurement was conducted at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds. The measurement was conducted with the cab doors and the cab windows closed. The cab was properly installed and maintained. |

| Sound (1) | Exterior Sound Pressure Level (ISO 6395:2008): 116 db(A) |

| Note (1) | The measurement was conducted at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds. |

| Note (2) | The sound levels listed above include both measurement uncertainty and uncertainty due to production variation. |

| Note (3) | The available sound suppression package can reduce the dynamic exterior sound power level of the machine by up to 4 db(A) and the dynamic operator sound pressure level by up to 2 db(A). |

| Specification | Value |

| 1.0 Forward | 4 km/h |

| 1.5 Forward | 5.4 km/h |

| 2.0 Forward | 7.2 km/h |

| 2.5 Forward | 9.6 km/h |

| 3.0 Forward | 12.5 km/h |

| 1.0 Reverse | 5.2 km/h |

| 1.5 Reverse | 6.7 km/h |

| 2.0 Reverse | 9 km/h |

| 2.5 Reverse | 12.1 km/h |

| 3.0 Reverse | 15.7 km/h |

| Transmission Clutch Diameter | 431.8 mm |

| Type | Planetary powershift |

| Specification | Value |

| Ground Clearance* | 725 mm |

| Track Gauge | 2.550 mm |

| Width - Without Trunnions - 610 mm/24 in ES | 3.311 mm |

| Width - Over Trunnions | 3.759 mm |

| Height - FOPS Cab* | 4.134 mm |

| Height - Top of Stack* | 4.356 mm |

| Height - ROPS/Canopy* | 4.406 mm |

| Note (1) | *Includes grouser height for total dimensions on hard surfaces. |

| Length - Track on Ground | 3.880 mm |

| Overall Length - Basic Tractor | 5.324 mm |

| Length - With SU-Blade | 7.416 mm |

| Length - With U-Blade | 7.750 mm |

| Length - With Single-Shank Ripper | 7.081 mm |

| Length - With Multi-Shank Ripper | 7.241 mm |

| Overall Length - SU-Blade/SS Ripper | 9.158 mm |

| Specification | Value |

| 10SU ABR - Capacity (SAE J1265) | 18.5 m³ |

| 10SU ABR - Width (over end bits) | 4.940 mm |

| 10SU ABR - Height | 2.120 mm |

| 10SU ABR - Digging Depth - Blade Pitch: Full Racked Back (Carry) | 507.47 mm |

| 10SU ABR - Digging Depth - Blade Pitch: Nominal | 640.87 mm |

| 10SU ABR - Digging Depth - Blade Pitch: Full Pitched Forward (Spread) | 764.12 mm |

| 10SU ABR - Ground Clearance - Blade Pitch: Full Racked Back (Carry) | 1.680 mm |

| 10SU ABR - Ground Clearance - Blade Pitch: Full Pitched Forward (Spread) | 1.368 mm |

| 10SU ABR - Ground Clearance - Maximum Tilt LH | 1.430 mm |

| 10SU ABR - Ground Clearance - Maximum Tilt RH | 1.430 mm |

| 10U ABR - Capacity (SAE J1265) | 22 m³ |

| 10U ABR - Width (over end bits) | 5.260 mm |

| 10U ABR - Height | 2.120 mm |

| 10U ABR - Digging Depth - Blade Pitch: Full Racked Back (Carry) | 507.5 mm |

| 10U ABR - Digging Depth - Blade Pitch: Nominal | 640.9 mm |

| 10U ABR - Digging Depth - Blade Pitch: Full Pitched Forward (Spread) | 764.1 mm |

| 10U ABR - Ground Clearance - Blade Pitch: Full Racked Back (Carry) | 1.680 mm |

| 10U ABR - Ground Clearance - Blade Pitch: Full Pitched Forward (Spread) | 1.368 mm |

| 10U ABR - Ground Clearance - Maximum Tilt LH | 1.545 mm |

| 10U ABR - Ground Clearance - Maximum Tilt RH | 1.545 mm |

| 10U ABR - Weights - Blade Weight* | 10.698 kg |

| 10U ABR - Weights - Total Operating Weight** (with blade and SS ripper) | 70.256 kg |

| Note (1) | Maximum LH and RH tilt for 10SU ABR and 10U ABR blades: 17.31 degrees |

| Note (2) | *Does not include hydraulic controls but includes blade cylinders, pusharms. |

| Note (3) | **D10 Operating Weight includes coolant, lubricants, full fuel tank, ROPS, FOPS cab, SU ABR bulldozer, dual tilt, single-shank ripper with pin-puller, fast fuel, 610 mm (24 in) ES shoes, and operator. |

| Specification | Value |

| Maximum penetration force * (shank vertical) | 219 kN |

| Maximum penetration depth (standard tip) | 1.504 mm |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | 912 mm |

| Weight | 6.445 kg |

| Note | Weight includes one shank. Add 544 kg (1,199 lb) for each additional shank. |

| Specification | Value |

| Maximum penetration force * (shank vertical) | 236 kN |

| Maximum penetration depth (standard tip) | 1.988 mm |

| Weight | 6.599 kg |

| Note | Weight includes one shank. Add 544 kg (1,199 lb) for each additional shank. |

Learn more information about the Cat D10 Dozer.

Download (2.22 MB, PDF)From pre-purchase consults to end-of-lifecycle benefits, Mantrac informs, advises and partners with you.

Speak with the Sales Team to learn the latest prices and information on products that can deliver value and help transform your business.

Find the perfect machine or equipment solution by contacting one of our local specialists. They are on standby, ready to help you solve your operational challenges.

Ask an Expert Today!