Fill out our form with your model of interest and we'll send you a downloadable brochure or technical specifications document.

The 785 Large Mining Truck was Caterpillar’s first entry into the mining industry more than three decades ago and has been a proven performer on sites around the world ever since. And now it’s the first to combine a game-changing level of efficiency with industry-leading physical availability to deliver the next generation of productive hauling. It all starts with the operator, who sits in a state-of-the-art environment designed for efficiency and equipped with features that increase comfort, automate functions, provide real-time information and boost confidence. The 785 also delivers significant improvements in serviceability and reliability, enhanced connectivity and easier technology integration. These improvements — and more — take an already proven truck to the next level of productivity.

The Advanced Power Electronic Control Strategy (APECS) enables faster cycle times thanks to more continuous torque and rimpull.For…

Wide, slip-resistant surfaces and hand rails, plus an optional powered access ladder, improve access and egress. Superior co…

The cab provides 34% more operator space than D-Series models. It�s 17% wider and offers 11% more legroom and 19% more shoulder ro…

Higher resolution displays improve access to information. Machine data, controls and guidance information are consolidated onto tw…

The new modular HVAC (heating, ventilation and air conditioning) system improves reliability and consolidates components so the en…

Longer-life components, extended service intervals and easier maintenance deliver consistently high mechanical availability. …

Caterpillar designed and manufactured bodies are integrated with the chassis as a unit to optimize performance and incorporate opt…

The 785 is designed to use less fuel, which reduces engine emissions, and there is zero fuel burn during retarding. The Tier 4 Fin…

The 785 is available in a cold-weather configuration that makes it ideal for mines operating in frigid environments. It features a…

MineStar Fleet is a fleet monitoring system that can be used to measure, manage and maximize the overall hauling operation. …

Next generation connectivity delivers faster data transfers, better access to data, consistent data communication, more actionable…

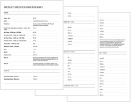

| Specification | Value |

| Gross Power - SAE J1995 | 1.193 kW |

| Net Power - SAE J1349 | 1.125 kW |

| Engine Model | Cat 3512E |

| Emissions Rating | Fuel Optimized |

| Bore | 170 mm |

| Stroke | 215 mm |

| Displacement | 58.56 l |

| Note (1) | Net Power advertised is the power available at the flywheel when the engine is equipped with air intake system, exhaust system, and alternator. |

| Note (2) | U.S. EPA Tier 4 Final / EU Stage V available for applicable markets. |

| Note (3) | Additional fuel optimized selectable power ratings: 1,450 hp |

| Specification | Value |

| Nominal Rated Payload (36.00R51 Tires) | 147 t |

| Rated Gross Machine Weight (36.00R51 tires) | 255.826 kg |

| Nominal Rated Payload (33.00R51 Tires) | 143 t |

| Rated Gross Machine Weight (33.00R51 tires) | 249.476 kg |

| Chassis Weight (33.00R51 Tires) | 85.156 kg |

| Chassis Weight (36.00R51 Tires) | 87.525 kg |

| Body Weight | 26.208 kg |

| Note (1) | Consult your tire manufacturer for maximum tire load |

| Note (2) | Chassis weight with full fuel and fluids, standard & mandatory attachments, hoist, body mounting group, rims, and tires. |

| Note (3) | Unlined HP Body. Body weight varies depending on body selection and configuration. |

| Specification | Value |

| Front Axle - Empty | 48% |

| Rear Axle - Empty | 52% |

| Front Axle - Loaded | 33% |

| Rear Axle - Loaded | 67% |

| Note | Weight distributions optimized with Cat body. |

| Specification | Value |

| Type | Double reduction, planetary with full floating axles. |

| Differential Ratio | 2:10:01 |

| Planetary Ratio | 10.83:1 |

| Total Reduction Ratio | 22.75:1 |

| Specification | Value |

| Forward - 1 | 12 km/h |

| Forward - 2 | 16.2 km/h |

| Forward - 3 | 22.1 km/h |

| Forward - 4 | 29.8 km/h |

| Forward - 5 | 40.2 km/h |

| Forward - 6 | 57.2 km/h |

| Reverse | 11.6 km/h |

| Top Speed - Loaded | 57.2 km/h |

| Note | Maximum travel speeds with standard 33.00-R51 tires. |

| Specification | Value |

| Optional Tires | 33.00R51 |

| Optional Tire | 36.00R51 |

| Rims | 610 mm (24") Rims (optional). 660 mm (26") Rims (optional). |

| Note (1) | Quick Change Rims optional. |

| Note (2) | Caterpillar recommends the customer evaluate all job conditions and consult tire manufacturer for proper tire selection and TKPH (TMPH) capabilities. |

| Specification | Value |

| Service Brakes | Four-Corner, Wet Disc, Oil Cooled, Hydraulically Actuated |

| Front Wet Disc Brake Surface Area | 61.270 cm² |

| Rear - Wet Disc Brake Surface Area | 89.728 cm² |

| Standards | Service and Secondary: ISO 3450:2011 |

| Parking Brake | Four corner, multi disc, spring applied, hydraulically released |

| Specification | Value |

| Type | Twin, two-stage hydraulic cylinders with snubbing valve. |

| Pump Flow - High Idle | 847 L/min |

| Relief Valve Setting - Raise | 17.225 kPa |

| Body Raise Time - High Idle | 15 s |

| Body Lower Time - Float | 15.6 s |

| Body Power Down- High Idle | 15.5 s |

| Specification | Value |

| Heaped (SAE 2:1)* | 110 m3 / 144 yd3 |

| Struck | 84 m3 / 110 yd3 |

| Specification | Value |

| Type | Self-contained nitrogen/oil cylinders, pin-to-pin mounting, top & bottom double shear clevis attachments |

| Effective Cylinder Stroke - Front | 320 mm |

| Effective Cylinder Stroke - Rear | 165 mm |

| Rear axle - Oscillation | +/- 5.4 degrees |

| Specification | Value |

| Fuel Tank | 1.552 l |

| Diesel Exhaust Fluid Tank | 136 l |

| Cooling System | 476 l |

| Crankcase | 204 l |

| Front Wheels - Each | 27 l |

| Differential - Final Drives | 527 l |

| Steering Tank | 110 l |

| Steering System - Includes Tank | 117 l |

| Brake/Hoist Tank | 511 l |

| Brake Hoist System - Includes Tank | 541 l |

| Torque Converter - Transmission System - Including Sump | 175 l |

| Specification | Value |

| Air Conditioning | HFC - 134A refrigerant: 24,500 Btu/h |

| Heater / Defroster | 33.300 Btu/h |

| ROPS Standards (1) | ROPS (Rollover Protective Structure) meets ISO 3471:2008 for Operator and ISO 13459:2012 for Trainer. |

| FOPS Standards | FOPS (Falling Objects Protective Structure) meets ISO 3449:2005 Level II for Operator and ISO 13459:2012 Level II for Trainer. |

| Specification | Value |

| Sound Standards | The operator sound pressure level, 77 dB(A) with direct drive and 75 dB9A) with optional clutch, tested to ISO 6396:2008. |

| Specification | Value |

| Steer Angle | 25.1 ° |

| Turning Diameter - ISO 7457:1997 (33.00R51 tires) | 29.4 m |

| Steering Standards | ISO 5010:2019 |

| Specification | Value |

| Height - Top of ROPS | 5.208 mm |

| Overall Body Length | 11.985 mm |

| Inside Body Length | 8.318 mm |

| Overall Length | 11.957 mm |

| Wheel Base | 5.180 mm |

| Rear Axle - Tail | 3.829 mm |

| Ground Clearance | 1.004 mm |

| Dump Clearance | 1.128 mm |

| Loading Height - Empty | 5.299 mm |

| Inside Body Depth - Maximum | 2.790 mm |

| Overall Height - Body Raised | 12.032 mm |

| Operating Width | 7.535 mm |

| Centerline Front Tire Width | 4.850 mm |

| Engine Guard Clearance | 1.038 mm |

| Overall Canopy Width | 7.562 mm |

| Outside Body Width | 6.714 mm |

| Inside Body Width | 6.010 mm |

| Front Canopy Height | 6.035 mm |

| Rear Axle - Clearance | 990 mm |

| Centerline of Rear Dual Tire Width | 4.285 mm |

| Overall Tire Width | 6.277 mm |

Learn more information about the Cat 785 Mining Truck (LRC, Tier 4 Final / EU Stage V).

Download (2.22 MB, PDF)From pre-purchase consults to end-of-lifecycle benefits, Mantrac informs, advises and partners with you.

Speak with the Sales Team to learn the latest prices and information on products that can deliver value and help transform your business.

Find the perfect machine or equipment solution by contacting one of our local specialists. They are on standby, ready to help you solve your operational challenges.

Mantrac Tanzania Ltd.

Plot no 4A

Nyerere Road

P.O. Box 9262

Dar es Salaam

Ask an Expert Today!