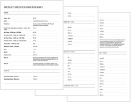

Fill out our form with your model of interest and we'll send you a downloadable brochure or technical specifications document.

When we invited our customers to help us design the first of our “Next Generation” Cat® hydraulic shovels, they gave us three top priorities: Make it safe, keep it simple and make it reliable. We responded by developing the Cat 6020B, which delivers the simplicity and versatility you desire, with valuable modern design features that set it apart from the competition.The 6020B offers class-leading visibility and a cab designed for comfort, safety and efficiency. A walk-through and exchangeable power module contributes to easier serviceability. The 6020B is 25% more fuel efficient than other shovels in its class, delivering efficiency and cost advantages. And the proven C32 engine meets emission standards without the need for DEF, saving time and cost during maintenance.

Operator Protective Guard (Top Guard) certified cab with safety glass windshield. Excellent visibility thanks to cab positio…

Quiet and fully pressurized cab with ergonomic operator seat and controls, superior insulation, extensive in-cab air distribution…

Better wear of undercarriage components thanks to floating push tube, which delivers even idler slide wear and extended component…

Up to 25% greater efficiency through Hydraulic Optimization, which dynamically assigns individual pumps or groups of pumps to deli…

Buckets and ground engaging tools (GET) designed to maximize durability and productivity and ideally matched to your shovel and ap…

Greater connectivity with improved Product Link™ Elite system, which increases the availability of data provided by the 6020B and…

Modular design that facilitates quick field assembly — as few as 14 days in typical condition. Exchangeable power module tha…

Highly regulated C32 engine certified to meet U.S. EPA Tier 4 Final/EU Stage V emissions standards without the need for DEF — savi…

| Specification | Value |

| Engine Output - SAE J1995 | 776 kW |

| Bucket Payload | 21.6 t |

| Operating Weight | 230.2 t |

| Note | Specifications shown above apply to a Backhoe configuration. A frontless configuration is also available. |

| Standard Bucket Capacity | 12 m³ |

| Specification | Value |

| Batteries (12V each) - In Series/Parallel Installation | 630 Ah – 24V |

| Components (3) | 9 LED high-brightness working flood lights: – 7 for working area<br>– 2 for rear end |

| Batteries (12V each) | 6 × 210 Ah |

| Components (1) | Emergency stop buttons inside cab, accessible from all seating locations, and engine module |

| Components (2) | Additional ground-level emergency stop |

| System Voltage | 24V |

| Battery Isolation Relays | manual lockable disconnect switch and automatic disconnect relay |

| Components (6) | 1 beacon lamp on cab roof |

| Components (5) | 7 LED service lights |

| Components (4) | 2 LED high-brightness access flood lights |

| Specification | Value |

| Features (2) | Variable electronically controlled flow of oil through cooler and fan speed |

| Oil Flow of Cooling Pumps | 800 l/min |

| Diameter - Fan | 1.500 mm |

| Features (1) | Cooling system fully independent of all main circuits, i.e. controlled cooling capacity available whenever engine is running |

| Features (3) | Superior cooling efficiency to ensure optimum oil temperature |

| Specification | Value |

| Components (5) | Full sized trainer seat with safety belt and work table |

| Internal Dimensions of Cab - Width | 1.625 mm |

| Components (7) | Operator Protective Guard (rock guard; approved according to ISO 10262:1998 [Top Guard]) compliant |

| Components (9) | Roller blinds |

| Components (11) | Additional emergency ladder in close proximity to emergency escape window |

| Internal Dimensions of Cab - Length | 2.230 mm |

| Components (8) | Windshield with parallel intermittent wiper/washer |

| Components (2) | Pneumatically cushioned and multi-adjustable operator seat with lumbar support, safety belt, head- and armrests |

| New BCS Features (1) | Robust instrument panel including large (254 mm/10 in) color touch screen |

| New BCS Features (3) | Graphical data logging |

| New BCS Features (4) | Fault memory capabilities |

| Operator's Eye Level (approximate) | 5.5 m |

| New BCS Features (2) | On-screen troubleshooting assistance |

| Components (10) | Machine access via retractable access stairway, stairway angle approximately 45°, hydraulically operated |

| New BCS Features (5) | USB, Lan (TCP/IP) and CAN BUS interfaces for data export |

| Components (3) | Safety switch in operator's seat for automatic motion shutdown |

| Internal Dimensions of Cab - Height | 2.070 mm |

| Components (1) | Large cab floor window with removable grating for easy cleaning |

| Components (4) | Joystick integrated in adjustable seat armrest |

| New Board Control System (BCS) Features: | Electronic monitoring, data logging and diagnostic system for vital signs & service data of engines, hydraulic & lube system |

| Components (6) | Auxiliary fold-away seat with safety belt for 3rd person |

| Specification | Value |

| Swing Ring | Triple-race roller bearing with sealed internal gearing |

| Maximum Swing Speed | 4.9 r/min |

| Swing Drive | 2 compact planetary transmissions with axial piston motors |

| Parking Brake | Wet multiple-disc brake, spring-loaded/hydraulically released |

| Features (2) | All slew ring raceways and grease tub for internal gearing supplied by automatic, central lubrication system |

| Features (1) | Open swing circuit with auto slow down when joysticks in neutral |

| Specification | Value |

| Track Pads - Each Side | 45 |

| Components (1) | Forged double-grouser track pads |

| Components (6) | Audible travel alarm |

| Bottom Rollers - Each Side | 8 |

| Travel Speed - 1st Stage - Maximum | 1.1 km/h |

| Components (4) | Fully hydraulic self-adjusting track tensioning system with accumulator |

| Components (5) | Automatic hydraulic retarder valve to prevent overspeed on downhill travel |

| Parking Brakes | Wet multiple disc brake, spring loaded/hydraulically released |

| Travel Speed - 2nd Stage - Maximum | 2.4 km/h |

| Gradeability - Travel Drives | Approximately 54% |

| Components (3) | All running surfaces of sprockets, idlers, rollers and track chain links hardened |

| Maximum Tractive Force | 1.183 kN |

| Travel Drives - Each Side | 1 planetary transmission with 2 two-stage axial piston motors |

| Components (2) | Chain links connected by hardened pins and bushings |

| Support Rollers - Each Side | 3 |

| Specification | Value |

| Type (3) | System condition and failures displayed by Board Control System |

| Capacity - Grease Barrel | 205 l |

| Type (1) | Single-circuit progressive system with hydraulically driven heavy-duty pump and electronic time control |

| Type (2) | Grease supplied to swing roller bearing, all pivot points of attachment, and swing gearbox bearing |

| Specification | Value |

| Type (5) | Float valve for boom down function |

| Type (2) | High-tensile steel with solid steel castings at pivot areas |

| Type (3) | Boom and stick stress-relieved after welding |

| Type (1) | Boom and stick torsion-resistant with welded box design |

| Type (4) | Catwalks with rails at boom |

| Buckets Equipped With | – Special liner material covering main wear areas inside and outside<br>– Lip shrouds<br>– Wing shrouds<br>– Heel shrouds |

| Specification | Value |

| Standard Track Pads | 800 mm |

| Operating Weight | 230.200 kg |

| Ground Pressure | 22 N/cm² |

| Specification | Value |

| Maximum Swing Oil Flow | 783 l/min |

| Maximum Pressure - Attachment | 310 bar |

| Filters (4) | Pressure filters (6 μm) for servo circuit |

| Electronic Pump Management Contains (3) | Automatic return of main pumps to zero flow |

| Features (2) | Cooling of pump transmission gear oil |

| Maximum Pressure - Travel | 310 bar |

| Maximum Pressure - Swing - Acceleration | 310 bar |

| Filters (3) | Full-flow filters (10 μm) for cooling return circuit |

| Electronic Pump Management Contains (2) | Dedicated circuit pump allocation |

| Maximum Total Oil Flow | 2.350 l/min |

| Filters (2) | Full-flow filters (10 μm) for complete return circuit |

| Main Pumps | 6 × variable swash plate pumps |

| Filters (1) | Full-flow high-pressure filters (100 μm) for main pumps, installed directly behind each pump |

| Electronic Pump Management Contains (4) | Automatic rpm reduction of engine speed during working breaks |

| Filters (5) | Transmission oil filter (40 μm) |

| Electronic Pump Management Contains (5) | Reduced oil flow of main pumps at high hydraulic oil temperature and at high engine temperature |

| Electronic Pump Management Contains (1) | Electronic load limit control |

| Features (1) | Pressure cut-off function for all main pumps |

| Total Volume of Hydraulic Oil | 3.500 l |

| Hydraulic Tank Capacity | 2.800 l |

| Maximum Pressure - Swing - Deceleration | 350 bar |

| Specification | Value |

| Equipped With (3) | Indicator light for hydraulic tank full |

| Equipped With (1) | Quick couplings for: – Diesel fuel<br>– Engine coolant<br>– Pump transmission gear oil<br>– Engine oil (oil pan)<br>– Hydraulic oil |

| Features | Centralized service area accessible from ground level. |

| Equipped With (2) | Cat jump-start socket |

| Specification | Value |

| Maximum Tearout Force | 650 kN |

| Maximum Breakout Force | 730 kN |

| Specification | Value |

| Maximum Digging Reach | 15.9 m |

| Maximum Digging Depth | 8.1 m |

| Maximum Digging Height | 13.9 m |

| Specification | Value |

| Operating Weight | 230 t |

| Bucket Payload | 22 t |

| Specification | Value |

| Standard Bucket Capacity - Backhoe (Heaped 1:1) | 12 m³ |

| Specification | Value |

| Gross Power - SAE J1995 | 776 kW |

| Engine Model | Cat C32 ACERT |

| Net Power - SAE J1349 | 770 kW |

| Specification | Value |

| Gross Power - SAE J1995 | 776 kW |

| Net Power - ISO 9249 | 774 kW |

| Net Power - SAE J1349 | 770 kW |

| Emissions | Meets China Nonroad Stage III emissions standards, equivalent to Tier 2 |

| Specification | Value |

| Components (1) | Cat NOx reduction system |

| Components (7) | Two-stage fuel filter |

| Components (3) | MEUI™-C fuel system |

| Alternator | 275A |

| Bore | 145 mm |

| Components (4) | Hydraulically driven radiator fan with variable electronically controlled fan speed |

| No. of Cylinders | 12 |

| Displacement | 32 l |

| Fuel Tank Capacity | 3.600 l |

| Components (5) | Micro processed engine management |

| Rated Speed | 1,800 min-1 (1,800 rpm) |

| Aspiration | Turbocharged and air-to-air aftercooled |

| Components (2) | Dual Diesel Oxidation Catalysts (DOCs) |

| Components (8) | Additional high-capacity water separator including electric priming pump |

| Components (9) | Large fuel tank allows for 24 hour machine operation |

| Components (6) | Heavy-duty air filters |

| Maximum Altitude without Deration | 2925 m (9,600 ft) – above sea level (a.s.l.) |

| Stroke | 162 mm |

| Make and Model | Cat C32 ACERT |

| Specification | Value |

| Components (3) | Heavy-duty air filters |

| Components (4) | Two-stage fuel filter |

| Fuel Tank Capacity | 3.600 l |

| No. of Cylinders | 12 |

| Components (2) | Micro processed engine management |

| Displacement | 32 l |

| Maximum Altitude without Deration | 3622 m (11,884 ft) – above sea level (a.s.l.) |

| Bore | 145 mm |

| Components (1) | Hydraulically driven radiator fan with variable electronically controlled fan speed |

| Stroke | 162 mm |

| Aspiration | Turbocharged and air-to-air aftercooled |

| Components (5) | Additional high-capacity water separator including electric priming pump |

| Rated Speed | 1800 min-1 (1,800 rpm) |

| Alternator | 275A |

| Make and Model | Cat C32 ACERT |

| Components (6) | Large fuel tank allows for 24 hour machine operation |

| Specification | Value |

| Gross Power - SAE J1995 | 771 kW |

| Net Power - ISO 9249 | 764 kW |

| Net Power - SAE J1349 | 761 kW |

| Emissions | Meets Tier 4 Final and Stage V emissions standards |

| Specification | Value |

| Net Power - SAE J1349 | 761 kW |

| Gross Power - SAE J1995 | 771 kW |

| Engine Model | Cat® C32 ACERT™ |

Learn more information about the Cat 6020B Hydraulic Shovel.

Download (2.22 MB, PDF)From pre-purchase consults to end-of-lifecycle benefits, Mantrac informs, advises and partners with you.

Speak with the Sales Team to learn the latest prices and information on products that can deliver value and help transform your business.

Find the perfect machine or equipment solution by contacting one of our local specialists. They are on standby, ready to help you solve your operational challenges.

Mantrac Tanzania Ltd.

Plot no 4A

Nyerere Road

P.O. Box 9262

Dar es Salaam

Ask an Expert Today!