Fill out our form with your model of interest and we'll send you a downloadable brochure or technical specifications document.

The productive and familiar Cat® D9 GC Dozer gives you performance and reliability in a simple, economical dozer. It’s easy to operate, simple to repair, and built with all Cat components that work together to deliver top performance and high availability. The D9 GC builds on the success of the versatile and durable D9R, which has been hard at work around the world for 25 years. The D9 GC’s major components, parts and systems will look familiar to those who have owned, operated and maintained the D9R. The D9 GC delivers unmatched reliability and long life through a proven design. A variety of application-specific configurations and attachments makes the D9 GC the ideal dozer for a variety of applications.

Cat three-speed planetary powershift transmission and well-known torque divider with free wheel stator put more power to the groun…

The suspended undercarriage absorbs impact and reduces shock loads transferred to the undercarriage by up to 50% for a smoother, m…

The operator station offers an exceptional viewing area, to give the operator a clear line of sight to front and rear work areas.…

The D9 GC is designed to be used in a variety of applications such as ripping overburden, production dozing, stockpiling, winching…

The Cat 3408C engine offers longer fuel and air cleaner life, a new self-tensioner and a single UHE oil filter. The high-eff…

The perfect match for the D9 GC, Cat blades are aggressive in tough materials and offer superior loadability. Cat blades hav…

The heavy, strong and durable frame features high-strength steel castings and continuously rolled top and bottom frame rails. Fram…

Like all Cat products, the D9 GC is supported by the global Cat dealer network — a one-of-a-kind, on-the-ground support network th…

Features like extended life filters and longer maintenance intervals decrease the amount of waste contributed to the environment.…

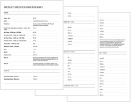

| Specification | Value |

| Engine Model | Cat® 3408C |

| Net Power - SAE J1349/ISO 9249 | 308 kW |

| Bore | 137 mm |

| Stroke | 152 mm |

| Displacement | 18 l |

| Engine Power - Gross SAE J1995* | 330 kW |

| Engine Power - ISO 14396 | 326 kW |

| Emissions | U.S. EPA Tier 1 Equivalent |

| Note (1) | All Engine ratings apply at 1,900 rpm. |

| Note (2) | No derating required up to 2250 m (7,381 ft) altitude. |

| Specification | Value |

| Fuel Tank (Splash Fill) | 963 l |

| Fuel Tank (Fast Fill) | 939 l |

| Cooling System | 99.8 l |

| Engine Crankcase* | 48 l |

| Powertrain | 150 l |

| Final Drives (each) | 15 l |

| Roller Frames (each) | 45 l |

| Pivot Shaft Oil | 30 l |

| Hydraulic System Tank | 89 l |

| Note | *With oil filters. |

| Specification | Value |

| Operating Weight | 49.441 kg |

| Shipping Weight | 37.724 kg |

| Note (1) | D9 Operating Weight includes hydraulic controls, blade tilt cylinder, coolant, lubricants, full fuel tank, ROPS, FOPS cab, SU Blade, Single-Shank Ripper, 610 mm (24 in) ES shoes and operator. |

| Note (2) | D9 Shipping Weight includes base machine chassis with cab, pivot shaft, roller frames, track and ROPS. |

| Specification | Value |

| Pump Type | Piston-type geared to flywheel |

| Pump Output - Implement | 235 L/min |

| Fan Pump | 72 L/min |

| Tilt Cylinder Flow - Rod End Flow | 137 L/min |

| Tilt Cylinder Flow - Head End Flow | 167 L/min |

| Lift Cylinder Relief Valve Setting | 26.200 kPa |

| Tilt Cylinder Relief Valve Setting | 19.300 kPa |

| Ripper - Lift - Relief Valve Setting | 26.200 kPa |

| Ripper - Pitch - Relief Valve Setting | 26.200 kPa |

| Note (1) | Implement Pump output measured are 1,900 engine rpm and 20000 kPa (2,900 psi). |

| Note (2) | Fan Pump output measured at 1,900 engine rpm and 17000 kPa (2,470 psi). |

| Specification | Value |

| Shoe Type | Extreme Service |

| Width - Shoe | 610 mm |

| Shoes/Side | 43 |

| Grouser Height | 84 mm |

| Pitch | 240 mm |

| Ground Clearance | 459 mm |

| Track Gauge | 2.250 mm |

| Length - Track on Ground | 3.470 mm |

| Ground Contact Area | 4.23 m² |

| Track Rollers/Side | 8 |

| Number of Carrier Rollers | 1 per side (optional) |

| Specification | Value |

| Steering Type | Clutch/Brake |

| Brake Type | Spring Applied Wet Disc |

| Brake Diameter | 393.7 mm |

| Brake Count | 8 |

| Steering Clutch Type | Pressure Applied Wet Disc |

| Steering Clutch Disc Diameter | 393.7 mm |

| Steering Clutch Disc Count | 6 |

| Specification | Value |

| Sound (2) | If equipped, the certification label is used to verify the environmental sound certification of the machine to the requirements of the “Technical Regulation of Noise Radiation into the Environment” for Ukraine. The value that is listed on the label indicates the guaranteed exterior sound power level (LWA) of 115 dBA at the time of manufacture for the conditions that are specified. |

| ROPS | ROPS (Rollover Protective Structure) offered by Caterpillar for the machine meets ROPS criteria ISO 3471:2008. |

| FOPS | FOPS (Falling Object Protective Structure) meets ISO 3449:2005 Level II. |

| Sound | The declared dynamic operator sound pressure level is 85 dB(A) when ISO 6396:2008 is used to measure the value for an enclosed cab. The measurement was conducted at 100% of the maximum engine cooling fan speed. The cab was properly installed and maintained. The measurement was conducted with the cab doors and the cab windows closed. |

| Sound (1) | Hearing protection may be needed when the machine is operated with an open operator station for extended periods or in a noisy environment. Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors and windows are open for extended periods or in a noisy environment. |

| Note | Brakes meet the standard ISO 10265. |

| Specification | Value |

| 1.0 Forward | 3.9 km/h |

| 2.0 Forward | 6.8 km/h |

| 3.0 Forward | 11.9 km/h |

| 1.0 Reverse | 4.7 km/h |

| 2.0 Reverse | 8.4 km/h |

| 3.0 Reverse | 14.7 km/h |

| Type | Planetary powershift |

| Specification | Value |

| Blade Capacity (SAE J1265) | 13.6 m³ |

| Blade Width (over end bits) | 4.376 mm |

| Blade Height | 1.934 mm |

| Maximum Digging Depth | 606 mm |

| Ground Clearance at Full Lift | 1.422 mm |

| Maximum Tilt | 940 mm |

| Blade Weight | 4.802 kg |

| Total Operating Weight* (with blade and single-shank ripper) | 49.441 kg |

| Note | * Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes, operator, the noted blade and single-shank ripper. |

| Specification | Value |

| Blade Capacity (SAE J1265) | 16.6 m³ |

| Blade Width (over end bits) | 4.648 mm |

| Blade Height | 1.934 mm |

| Maximum Digging Depth | 606 mm |

| Ground Clearance at Full Lift | 1.422 mm |

| Maximum Tilt | 1.014 mm |

| Blade Weight | 5.327 kg |

| Total Operating Weight* (with blade and single-shank ripper) | 49.966 kg |

| Note | * Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type. |

| Specification | Value |

| Maximum penetration force * (shank vertical) | 158 kN |

| Maximum penetration depth (standard tip) | 1.231 mm |

| Pryout Force | 332 kN |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | 882 mm |

| Number of Pockets | 1 |

| Weight | 4.293 kg |

| Total Operating Weight* (with SU Blade and noted ripper) | 49.441 kg |

| Note | * Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes, operator, SU Blade and noted ripper. |

| Specification | Value |

| Maximum penetration force * (shank vertical) | 172 kN |

| Maximum penetration depth (standard tip) | 1.727 mm |

| Pryout Force | 331 kN |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | 817 mm |

| Number of Pockets | 1 |

| Weight | 4.420 kg |

| Total Operating Weight* (with SU Blade and noted ripper) | 49.568 kg |

| Note | * Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes, operator, SU Blade and noted ripper. |

| Specification | Value |

| Maximum Penetration Force - Shank Vertical | 154 kN |

| Maximum Penetration - Standard Tip | 798 mm |

| Pry-Out Force - Multi-Shank Ripper with One Tooth | 361 kN |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | 879 mm |

| Number of Pockets | 3 |

| Weight | 4.153 kg |

| Total Operating Weight* - With SU-Blade and Ripper | 49.301 kg |

| Note | * Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes, operator, SU Blade and noted ripper. Includes (1) shank; add 347 kg (765 lb) for each additional shank. |

| Specification | Value |

| Winch Model | PA 140VS |

| Weight* | 1.790 kg |

| Oil Capacity | 15 l |

| Increased Tractor Length | 557 mm |

| Drum Width | 320 mm |

| Wire Cable Diameter - Recommended | 28 mm |

| Wire Cable Diameter - Optional | 32 mm |

| Maximum Drum Capacity - Recommended Cable Length | 78 m |

| Maximum Drum Capacity - Optional Cable Length | 62 m |

| Wire Cable Ferrule Size - Outside Diameter | 60 mm |

| Wire Cable Ferrule Size - Length | 70 mm |

| Note | *Weight shown is base winch only. Does not include mounting arrangement, control arrangement, oil or wire rope. With counterweight: 3700 kg (8,150 lb). |

| Note (2) | Variable speed, hydraulically driven, dual braking system, three-roller fairlead. |

| Specification | Value |

| Ground Clearance* | 459 mm |

| Track Gauge | 2.250 mm |

| Width - Without Trunnions - Standard Shoe | 2.870 mm |

| Width - Over Trunnions | 3.310 mm |

| Height - FOPS Cab* | 3.820 mm |

| Height - Top of Stack* | 3.876 mm |

| Height - ROPS/Canopy* | 4.000 mm |

| Drawbar Height (Center of Clevis)* | 763 mm |

| Length - Track on Ground | 3.470 mm |

| Overall Length - Basic Tractor | 4.910 mm |

| Length - Basic Tractor - With Drawbar | 5.242 mm |

| Length - Basic Tractor - With Winch | 5.545 mm |

| Length - With SU-Blade** | 6.601 mm |

| Length - With U-Blade | 6.967 mm |

| Length - With Single-Shank Ripper | 6.529 mm |

| Length - With Multi-Shank Ripper | 6.538 mm |

| Overall Length - SU-Blade/SS Ripper | 8.219 mm |

| Note (1) | *Includes grouser height for total dimensions on hard surfaces. |

Learn more information about the Cat D9 GC Dozer.

Download (2.22 MB, PDF)From pre-purchase consults to end-of-lifecycle benefits, Mantrac informs, advises and partners with you.

Speak with the Sales Team to learn the latest prices and information on products that can deliver value and help transform your business.

Find the perfect machine or equipment solution by contacting one of our local specialists. They are on standby, ready to help you solve your operational challenges.

Shanghai Offshore Office

Minhang District, Shanghai, China