Fill out our form with your model of interest and we'll send you a downloadable brochure or technical specifications document.

The Cat® 730 features a world-class cab design, re-engineered using global operator feedback to advance comfort and ease of operation. Enhancements include new controls, transmission-protection features, hoist-assist system, advanced automatic traction control system, stability-assist machine rollover warning system, and a fuel saving ECO mode.

Every Tier 2/Stage II equivalent Cat engine is equipped with a combination of proven electronic, fuel, air and aftertreatment comp…

The Cat CX31 six-speed forward, single-speed reverse transmission features Advanced Productivity Electronic Control Strategy (APEC…

Advanced automatic traction control (AATC) is a proactive application of the inter- and cross-axle differential locks is ‘on-the-g…

The new cab is designed to make all aspects of machine operation as simple as possible for every operator. The controls and gauges…

The large open cab offers a comfortable working space for both the operator and an additional person (e.g. training purposes). The…

All three axles have oscillating A-frames with lateral tie rods, controlling sideways movement of the axle and providing stability…

The front frame design features a large box section and wide, stiff frame beams to handle torque loads. The divergent frame design…

Cat Product Link wirelessly connect you to your equipment, giving you valuable insight into how your machine or fleet is performin…

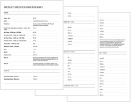

| Specification | Value |

| Engine Model | Cat® C13 |

| Gross Power (SAE J1995) | 280 kW |

| Net Power (SAE J1349) | 274 kW |

| Engine Power (ISO 14396) | 276 kW |

| Bore | 130 mm |

| Stroke | 157 mm |

| Displacement | 12.5 l |

| Note (1) | Advertised power is tested at 1,800 rpm. |

| Note (2) | Advertised power is tested per the specified standard in effect at the time of manufacture. |

| Note (3) | The net power advertised is the power available at the flywheel when the engine is equipped with alternator, air cleaner, muffler, and fan at minimum speed. |

| Note (4) | Net power when the fan is at maximum speed is 254 kW (341 hp) per the SAE reference conditions. |

| Note (5) | Equivalent to U.S. EPA Tier 2/EU Stage II or meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3/EU Stage IIIA. |

| No Engine De-rating Below | 3.810 m |

| Peak Engine Torque Gross (SAE J1995) | 2.141 N·m |

| Peak Engine Torque Net (SAE J1349) | 2.107 N·m |

| Peak Engine Torque Speed | 1.200 r/min |

| Specification | Value |

| Rated Payload | 28 t |

| Specification | Value |

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. • If equipped with R134a (Global Warming Potential = 1430), the system contains 1.1 kg (2.4 lb) of refrigerant which has a CO2 equivalent of 1.716 metric tonnes (1.891 tons). |

| Specification | Value |

| Heaped (SAE 2:1) | 17.5 m³ |

| Struck | 13.3 m³ |

| Tailgate Heaped SAE 2:1 | 18.8 m³ |

| Tailgate Struck | 13.9 m³ |

| Specification | Value |

| Forward - 1 | 8 km/h |

| Forward - 2 | 15 km/h |

| Forward - 3 | 22 km/h |

| Forward - 4 | 34 km/h |

| Forward - 5 | 47 km/h |

| Forward - 6 | 55 km/h |

| Reverse - 1 | 9 km/h |

| Specification | Value |

| Interior Cab | 72 dB(A) |

| Note (1) | The declared dynamic operator sound pressure level is 72 dB(A) when ISO 6396:2008 is used to measure the value for an enclosed cab. The measurement was conducted at 70% of the cooling fan’s maximum speed. The sound level may vary at different cooling fan speeds. The measurement was conducted with the cab doors and the cab windows closed. The cab was properly installed and maintained. |

| Note (2) | Hearing protection may be needed when operating with an open operator station and cab or when not properly maintained or with doors/windows open for extended periods or in noisy environments. |

| Specification | Value |

| Front Axle - Empty | 15.000 kg |

| Center Axle - Empty | 4.560 kg |

| Rear Axle - Empty | 4.340 kg |

| Total - Empty | 23.900 kg |

| Front Axle - Rated Load | 3.280 kg |

| Center Axle - Rated Load | 12.360 kg |

| Rear Axle - Rated Load | 12.360 kg |

| Total - Rated Load | 28.000 kg |

| Front Axle - Loaded | 18.280 kg |

| Center Axle - Loaded | 16.920 kg |

| Rear Axle - Loaded | 16.700 kg |

| Total - Loaded | 51.900 kg |

| Specification | Value |

| Type | High strength Brinell HB450 wear resistant steel |

| Specification | Value |

| Front Plate | 7 mm |

| Base Plate | 13 mm |

| Side Plates | 11 mm |

| Specification | Value |

| Fuel Tank | 412 l |

| Cooling System | 83 l |

| Hydraulic System | 110 l |

| Engine Crankcase | 38 l |

| Transmission | 47 l |

| Final Drives/Differential | 125 l |

| Output Transfer Gear Box | 24 l |

| Specification | Value |

| Raise Time | 12 s |

| Lower Time | 8 s |

| Specification | Value |

| Brakes | ISO 3450:2011 |

| Cab - FOPS | ISO 3449:2005 Level II |

| Cab - ROPS | ISO 3471 – 2008 |

| Steering | ISO 5010:2019 |

| Specification | Value |

| Turning Dimensions - Steer Angle - Left/Right | 45° |

| Turning Dimensions - SAE Turning Radius | 7.470 mm |

| Turning Dimensions - Clearance Radius | 8.075 mm |

| Turning Dimensions - Inside Radius | 3.879 mm |

| Turning Dimensions - Aisle Width | 5.332 mm |

| Note | Dimensions are for machines equipped with 23.5R25 tires. |

| Specification | Value |

| Lock to Lock | 4.75 seconds @ 60 rpm |

| Specification | Value |

| Hydraulic Excavators: 349/352 - Passes | 4-5 |

| Hydraulic Excavators: 336 - Passes | 5-6 |

| Wheel Loaders: 972/972 XE - Passes | 3-4 |

| Wheel Loaders: 966/966 XE - Passes | 4 |

| Wheel Loader: 962 - Passes | 4-5 |

| Wheel Loader: 950 - Passes | 5 |

| Note | An optimum system match gives you a major productivity advantage. The 730 is an excellent match for the Cat 349/352 and 336 Hydraulic Excavators; and Cat 972, 966, 962 and 950 Wheel Loaders. Having matched loading and hauling tools results in increased production and lower system costs per unit of volume moved. |

Learn more information about the Cat 730 Articulated Truck.

Download (2.22 MB, PDF)From pre-purchase consults to end-of-lifecycle benefits, Mantrac informs, advises and partners with you.

Speak with the Sales Team to learn the latest prices and information on products that can deliver value and help transform your business.

Find the perfect machine or equipment solution by contacting one of our local specialists. They are on standby, ready to help you solve your operational challenges.

Shanghai Offshore Office

Minhang District, Shanghai, China