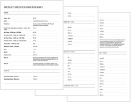

Fill out our form with your model of interest and we'll send you a downloadable brochure or technical specifications document.

The next generation Cat® 6015 Hydraulic Shovel lets you move more material at a low cost, so you can achieve production targets, deliver on your commitments, meet deadlines and maximize your profitability. With high tool carrying capacity, increased durability and the most powerful engine in its class, the Cat 6015 generates higher productivity and fuel efficiency than other shovels. And it’s offered with more and better options that let you match your machine to your operation — from access and cold weather packages to multiple stick and track pad options. In addition, a large range of buckets is available, giving you optimum payload and machine efficiency for your operation. And the 6015’s high tool carrying capacity gives you the ability to employ large buckets and move more in fewer cycles.

Safety glass, armored windshield and operator protective guards keep operators safe from hazardous condit…

State-of-the-art cab offers increased comfort and control to help operators work harder and last longer. &…

Reliable, durable C27 engine, which delivers top performance over a long life in a variety of application…

Load Enhanced Anticipatory Control ensures faster and more consistent engine regulation by preventing lug…

Robust major structures are designed to exacting standards and made with high-strength steel and castings…

Enhanced warning levels for hydraulic oil temperature and visual inspection ports for slew drive pinions…

Greater connectivity with improved Product Link™ Elite system, which increases the availability of data p…

Buckets and ground engaging tools (GET) designed to maximize durability and productivity and ideally matc…

Highly regulated C27 engines that meet U.S. EPA Tier 4 Final and EU Stage V emission requirements and eli…

| Specification | Value |

| Engine Output - SAE J1995 | 615 kW |

| Bucket Payload | 14.6 t |

| Operating Weight | 140 t |

| Note | Specifications shown above apply to highly regulated, backhoe configuration. Lesser regulated and frontless configurations are also available. |

| Specification | Value |

| Engine Model | Cat® C27 |

| Gross Power - SAE J1995 | 615 kW |

| Net Power - SAE J1349 | 606 kW |

| Specification | Value |

| Number of Cylinders | 12 |

| Bore | 137.2 mm |

| Stroke | 152.4 mm |

| Displacement | 27 l |

| Specification | Value |

| Engine Model | Cat® C27 |

| Gross Power - SAE J1995 | 626 kW |

| Net Power - SAE J1349 | 618 kW |

| Specification | Value |

| Number of Cylinders | 12 |

| Bore | 137.2 mm |

| Stroke | 152.4 mm |

| Displacement | 27 l |

| Aspiration | Turbocharged and air-to-air aftercooled |

| Specification | Value |

| Emissions | U.S. EPA Tier 4 Final and EU Stage V; China Nonroad Stage III, equivalent to U.S. EPA Tier 2; Equivalent to U.S. EPA Tier 1 |

| Specification | Value |

| Operating Weight | 140 t |

| Specification | Value |

| Ground Pressure | 16.3 N/cm² |

| Note | Operating weight includes: 700 mm (28 in) track pads, 7.6 m (24 ft 11 in) boom, 3.4 m (11 ft 2 in) stick, standard rock bucket, 100% fuel and lubricants |

| Operating Weight | 140.000 kg |

| Specification | Value |

| Standard | 700 mm |

| Wide | 900 mm |

| Extra Wide | 1.000 mm |

| Number of Shoes - Each Side | 46 |

| Number of Track Rollers - Each Side | 9 |

| Number of Carrier Rollers - Each Side | 3 |

| Track Pads | Heavy Duty (HD) with double grouser |

| Specification | Value |

| Travel Speed - Two Stages - 1st Stage - Maximum | 2.6 km/h |

| Travel Speed - Two Stages - 2nd Stage - Maximum | 3.7 km/h |

| Maximum Drawbar Pull - Forward | 858 kN |

| Maximum Drawbar Pull - Reverse | 983 kN |

| Gradeability - Travel Drives | Approximately 42% |

| Hydraulic Track Tensioning | With accumulator |

| Maximum Drawbar Pull | 800 kN |

| Specification | Value |

| Fuel Tank | 1.700 l |

| Cooling System | 165 l |

| Engine Oil | 87 l |

| Swing Drive | 9 l |

| Hydraulic System - Including Tank | 1.752 l |

| Hydraulic Tank | 956 l |

| Grease Tank | 215 l |

| Specification | Value |

| System Voltage | 24 V |

| Batteries | 4 × 200 Ah (12 V each) |

| Alternator Rating | 150 A (24 V) in total |

| Components (1) | Emergency stop switches: one in cab, three in engine module, one pull rope accessible from ground level |

| Components (2) | Four maintenance free batteries |

| Components (3) | Lockable battery isolation switch |

| Components (5) | 14 LED high-brightness working lights |

| Components (4) | 5 LED service lights |

| Components (6) | 2 electric horns |

| Components (7) | Two (2) lights for rear end |

| Components (9) | One (1) beacon light on cabin roof |

| Components (8) | One (1) light for machine deck/service |

| Specification | Value |

| Main Pumps | 3 × variable swash plate pumps |

| Main Pumps - Maximum Total Oil Flow | 1.544 L/min |

| Main Pumps - Maximum Pressure - Attachment | 320 bar |

| Pilot Pump - Maximum Flow, Pilot | 153 L/min |

| Pilot Pump | 1 × gear pump |

| Pilot Pump - Maximum Pressure, Pilot | 95 bar |

| Main Pumps - Maximum Pressure - Travel | 320 bar |

| Engine Fan Pump - Maximum Flow, Engine Fan | 201 L/min |

| Engine Fan Pump - Maximum Pressure, Engine Fan | 220 bar |

| Swing Pump | 1 × variable swash plate pump |

| Engine Fan Pump | 1 × variable swash plate pump |

| Swing Pump - Maximum Flow - Swing | 479 L/min |

| Hydraulic Fan Pump - Maximum Pressure, Hydraulic Fan | 135 bar |

| Hydraulic Fan Pump - Maximum Flow, Hydraulic Fan | 86 L/min |

| Hydraulic Fan Pump | 1 × variable swash plate pump |

| Swing Pump - Maximum Pressure - Swing | 365 bar |

| Hydraulic Oil Cooling - Maximum Flow | 1.075 L/min |

| Hydraulic Oil Cooling - Diameter of Fan | 1.168 mm |

| Filters (1) | Full-flow high-pressure filters (200 μm) for main pumps |

| Filters (2) | Full-flow filters (20 μm), return circuit |

| Filters (3) | Pressure filters (16 μm), servo circuit |

| Filters (4) | Full-flow filters (6 μm), cooling return circuit |

| Filters (5) | Swing charge filter (15 μm) |

| Filters (6) | Pump case return screens (125 μm) |

| Specification | Value |

| Swing Drive | Two (2) compact planetary transmissions with axial piston motors |

| Parking Brake | Wet multiple disc brake, spring-loaded/hydraulically released |

| Maximum Swing Speed | 4.9 r/min |

| Swing Ring | Triple-race roller bearing with sealed internal greasing |

| Features (1) | Closed-loop with torque control |

| Features (2) | Hydraulic braking of swing motion when control is returned to neutral position or by counteracting control for stronger braking |

| Features (3) | All raceways and the internal gearing of swing ring supplied by automatic central lubrication system |

| Specification | Value |

| Feature | Accessible from ground level for diesel fuel and grease |

| Equipped With (1) | One pull rope emergency stop |

| Equipped With (2) | Quick couplings for: diesel fuel and grease |

| Specification | Value |

| Travel Speed - Two Stages - 1st Stage - Maximum | 2.6 km/h |

| Travel Speed - Two Stages - 2nd Stage - Maximum | 3.7 km/h |

| Maximum Tractive Force | 877 kN |

| Maximum Drawbar Pull - Reverse | 983 kN |

| Gradeability - Travel Drives | 38°/78% (SAE J1309) |

| Number of Shoes - Each Side | 46 |

| Hydraulic Track Tensioning | With accumulator |

| Number of Track Rollers - Each Side | 9 |

| Number of Carrier Rollers - Each Side | 3 |

| Components (1) | Heavy Duty (HD) with double-grouser track pads |

| Components (2) | Chain links connected by hardened pins and bushings |

| Components (3) | Postive Pin Retention (PPR2) sealed and greased track design |

| Components (4) | Hardened running surfaces of sprockets, idlers, rollers and track chain links |

| Components (5) | Fully hydraulic self-adjusting track tensioning system with accumulator |

| Components (6) | Automatic hydraulic retarder valve |

| Components (7) | Acoustic travel alarm (forward and reverse) |

| Specification | Value |

| Components (1) | Pressurized cab with positive filtration |

| Components (2) | Heated cab mirror |

| Components (3) | Sliding upper door window |

| Components (4) | Glass-breaking safety hammer |

| Components (5) | Removeable lower windshield within cab storage |

| Components (6) | Joystick Controls Alternate Patterns including ISO/JIS, BHL, MHI, KOBE, or SCM |

| Components (7) | Beverage holder |

| Components (8) | Literature holder |

| Components (9) | AM/FM radio |

| Components (10) | FM/AM radio with MP3 auxiliary port |

| Components (11) | Two stereo speakers |

| Components (12) | Storage shelf suitable for lunch or toolbox |

| Components (13) | Color LCD display with service parameters, event and diagnostic annunciation, preventative maintenance, trip total, lifetime totals. Gauges for engine speed, engine oil pressue, and hydraulic oil temperature |

| Components (14) | Head and arm rests |

| Components (15) | Independently adjustable seat consoles with integrated joysticks |

| Components (16) | Neutral lever (lock out) for all controls |

| Components (17) | Travel control pedals with removable hand levers |

| Components (18) | Two power outlets, 10 amp (total) |

| Components (19) | Laminated front upper window and tempered glass other windows |

| Specification | Value |

| Capacity - Grease Barrel | 68 l |

| Type (1) | Central bank lubrication system |

| Type (2) | Grease is automatically applied to all attachment pivot points, slew bearing, and bucket linkage |

| Type (3) | Standard grease reel on machine for bucket linkage |

| Type (4) | Grease refill service point accessible from ground |

| Specification | Value |

| Type (1) | Boom and stick torsion-resistant with welded box design |

| Type (2) | High-tensile steel with solid steel castings at pivot areas |

| Type (3) | Boom and stick stress-relieved after welding |

| Type (4) | Float valve for boom down function |

| Buckets Equipped With | – Special liner material covering main wear areas inside and outside – Lip shrouds – Wing shrouds – Heel shrouds |

| Specification | Value |

| Maximum Digging Depth | 8 m |

| Maximum Digging Reach | 13.9 m |

| Maximum Digging Height | 12.8 m |

| Maximum Dump Height | 8.5 m |

| Specification | Value |

| Bucket Digging Force - SAE | 501 kN |

| Bucket Digging Force - ISO | 538 kN |

| Stick Digging Force - ISO | 466 kN |

| Stick Digging Force - SAE | 439 kN |

| Specification | Value |

| Capacity 1:1 | 8.1 m³ |

| Total Width | 2.682 mm |

| Number of Teeth | 5 |

| Tooth System | Cat C70 or M75 |

| Weight - Including Standard Wear Package | 8.401 kg |

| Maximum Material Density - Loose | 1.8 t/m³ |

Learn more information about the Cat 6015 Hydraulic Shovel.

Download (2.22 MB, PDF)From pre-purchase consults to end-of-lifecycle benefits, Mantrac informs, advises and partners with you.

Speak with the Sales Team to learn the latest prices and information on products that can deliver value and help transform your business.

Find the perfect machine or equipment solution by contacting one of our local specialists. They are on standby, ready to help you solve your operational challenges.

Shanghai Offshore Office

Minhang District, Shanghai, China