Fill out our form with your model of interest and we'll send you a downloadable brochure or technical specifications document.

The Cat® 320 GC excavator balances productivity with easy-to-use technology features, a comfortable cab, reduced fuel consumption by up to 20%, and longer maintenance intervals reducing maintenance costs by up to 20% to bring you a durable, low-cost-per-hour excavator for light- to medium-duty applications.

Cab Monitor Improvements Continuously improved user interface all…

The excavator uses up to 20% less fuel than the 320D2 GC in similar applications. &nbs…

Expect up to 20% less maintenance cost than the 320D2 GC (savings calculated over 12,000 machine hours).…

Work up to 3000 m (9,840 ft) above sea level without de-rating. Standard h…

Access 100% of daily maintenance points from ground level – no need for you to climb on top of the excava…

Start the engine with a push button; use a Bluetooth® key fob, or the unique Operator ID function. …

The Comfort cab has a wide seat that adjusts for operators of all sizes. C…

VisionLink® provides actionable data insights for all assets - regardless of fleet size or equipment manu…

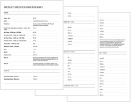

| Specification | Value |

| Net Power - ISO 9249 | 107 kW |

| Net Power - ISO 9249 (DIN) | 145 hp (metric) |

| Engine Model | Cat C4.4 |

| Engine Power - ISO 14396 | 108 kW |

| Engine Power - ISO 14396 (DIN) | 147 hp (metric) |

| Bore | 105 mm |

| Stroke | 127 mm |

| Displacement | 4.4 l |

| Biodiesel Capability | Up to B20¹ |

| Emissions | Meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA. |

| Note (1) | Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system, and alternator with engine speed at 2,000 rpm. Advertised power is tested per the specified standard in effect at the time of manufacture. |

| Note (2) | ¹Cat engines are compatible with diesel fuel blended with the following lower-carbon intensity fuels** up to: 100% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. *For use of blends higher than 20% biodiesel, consult your Cat dealer. **Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. |

| Specification | Value |

| Main System - Maximum Flow | 429 l/min (113 gal/min) |

| Maximum Pressure - Equipment | 35.000 kPa |

| Maximum Pressure - Travel | 34.300 kPa |

| Maximum Pressure - Swing | 25.000 kPa |

| Specification | Value |

| Swing Speed | 11.3 r/min |

| Maximum Swing Torque | 74.4 kN·m |

| Specification | Value |

| Operating Weight | 20.400 kg |

| Note | Medium undercarriage, Reach boom, R2.9 (9'6") stick, General Duty (GD) 1.0 m³ (1.31 yd³) bucket, 600 mm (24") triple grouser shoes, and 3.7 mt (8,200 lb) counterweight. |

| Specification | Value |

| Fuel Tank Capacity | 345 l |

| Cooling System | 25 l |

| Engine Oil | 15 l |

| Swing Drive - Each | 12 l |

| Final Drive - Each | 4 l |

| Hydraulic System - Including Tank | 234 l |

| Hydraulic Tank | 115 l |

| Specification | Value |

| Boom | Reach 5.7 m (18'8") |

| Stick | Reach 2.9 m (9'6") |

| Bucket | 1.0 m³ (1.31 yd³) |

| Shipping Height - Top of Cab | 2.960 mm |

| Handrail Height | 2.950 mm |

| Shipping Length | 9.530 mm |

| Tail Swing Radius | 2.830 mm |

| Counterweight Clearance | 1.050 mm |

| Ground Clearance | 470 mm |

| Track Length | 4.250 mm |

| Length to Center of Rollers | 3.450 mm |

| Track Gauge | 2.380 mm |

| Transport Width | 2.980 mm |

| Specification | Value |

| Maximum Digging Depth | 6.630 mm |

| Boom | Reach 5.7 m (18'8") |

| Stick | Reach 2.9 m (9'6") |

| Bucket | 1.0 m³ (1.31 yd³) |

| Maximum Reach at Ground Level | 9.770 mm |

| Maximum Cutting Height | 9.440 mm |

| Maximum Loading Height | 6.580 mm |

| Minimum Loading Height | 2.260 mm |

| Maximum Depth Cut for 2440 mm (8 ft) Level Bottom | 6.460 mm |

| Maximum Vertical Wall Digging Depth | 6.010 mm |

| Bucket Digging Force - ISO | 129 kN |

| Stick Digging Force - ISO | 99 kN |

Learn more information about the Cat 320 GC Hydraulic Excavator.

Download (2.22 MB, PDF)From pre-purchase consults to end-of-lifecycle benefits, Mantrac informs, advises and partners with you.

Speak with the Sales Team to learn the latest prices and information on products that can deliver value and help transform your business.

Find the perfect machine or equipment solution by contacting one of our local specialists. They are on standby, ready to help you solve your operational challenges.

Ask an Expert Today!